Address:NO.469 Fengjin Road Fengxian Shanghai P.R.C

Zip Code:201401

Tel:+86-021-18621776852

Fax:+86-021-60942287

Email: mary@shxinqiucn.com

steven@shxinqiucn.com

URL: http://www.shxinqiucn.com

http://Www.shxinqiucn.top

Non expansion seal gasket is in high temperature resistant ceramic fiber as raw materials,sealing mat without vermiculite components.

Technical parameters

|

|

1000 |

1100 |

1200 |

1300 |

1400 |

1540 |

2100 |

|

Weight tolerance |

10% |

10% |

10% |

10% |

10% |

10% |

10% |

|

Weight limit (g/m2) |

900 |

990 |

1080 |

1170 |

1260 |

1386 |

1890 |

|

Weight limit (g/m2) |

1100 |

1210 |

1320 |

1430 |

1540 |

1694 |

2310 |

|

Unit thickness (mm) |

6.90 |

7.60 |

8.30 |

9.00 |

9.70 |

10.60 |

14.50 |

|

Thickness tolerance |

10% |

10% |

10% |

10% |

10% |

10% |

10% |

|

Thickness limit (mm) |

6.20 |

6.70 |

7.30 |

8.10 |

8.70 |

9.50 |

13.10 |

|

Thickness limit(mm) |

7.60 |

8.50 |

9.30 |

9.90 |

10.70 |

11.70 |

16.00 |

|

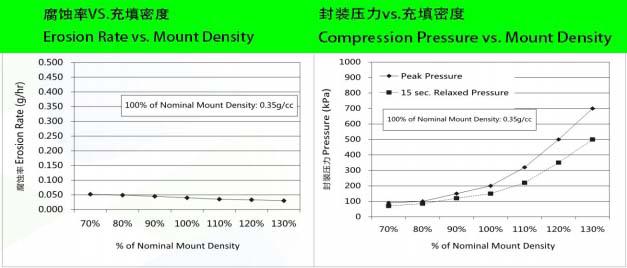

Packing density (g/cm3) |

0.35 |

0.35 |

0.35 |

0.35 |

0.35 |

0.35 |

0.35 |

|

Filing density range (g/cm3) |

0.25-0.50 |

0.25-0.50 |

0.25-0.50 |

0.25-0.50 |

0.25-0.50 |

0.25-0.50 |

0.25-0.50 |

|

Applicable gap lower limit (mm) |

2.22 |

2.44 |

2.67 |

2.88 |

3.11 |

3.42 |

4.88 |

|

Upper bound for application(mm) |

4.00 |

4.44 |

4.80 |

5.20 |

5.56 |

6.12 |

8.80 |

|

Burning loss (%) |

9-13 |

9-13 |

9-13 |

9-13 |

9-13 |

9-13 |

9-13 |

|

Tensile strength (kPa) |

≥100 |

≥100 |

≥100 |

≥100 |

≥100 |

≥100 |

≥100 |